The New Carbon Factors

The world of energy modelling and CO2 emission profiling has changed, significantly. In fact it is hard to overstate how dramatic this change is (in the world of energy) when it comes to determining the strategy to be employed for energy consuming assets. The first piece of policy to recognise this comes from the GLA; ‘Guidance on Energy Assessments’, published in October 2018.

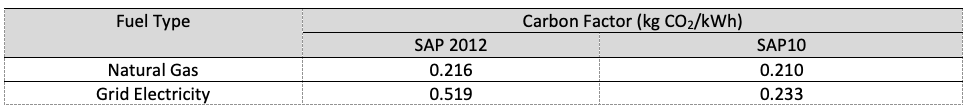

Grid electricity has significantly decarbonised since the last update of Part L in April 2014 and, in July 2018, the Government published updated carbon dioxide emission factors (SAP 10) demonstrating this. Although SAP 10 is not in use yet, the GLA Guidance encourages the use of SAP 10 carbon dioxide emission factors from January 2019 for planning applications. Using the older SAP 2012 emissions factors requires adequate robust justification. The revised factors are provided below:

Grid electricity has decarbonised by 55%, a staggering amount, which is in part is due to UK government policy over the last several years in decarbonising the grid. This is the result of significant deployment of renewables and the retiring of coal plant, in fact the EU will hit its renewable energy targets primarily because of two countries; Germany and the UK.

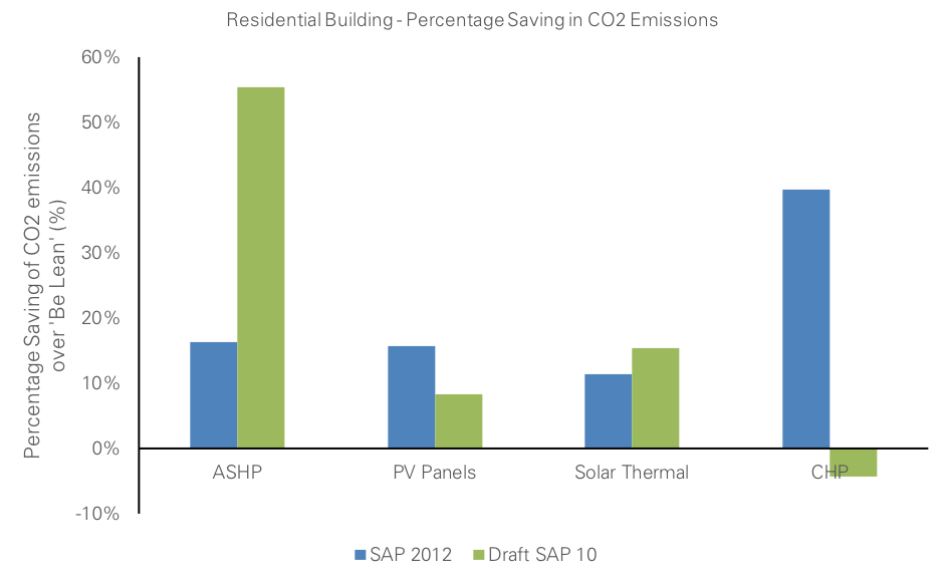

So what does this mean for development and building design? Following GLA guidance and using the draft SAP 10 carbon factors for the purposes of the CO2 calculations results in the air source heat pumps (ASHP) providing a huge saving and Combined Heat and Power (CHPs) plant providing a negative impact i.e. a carbon penalty compared to a standard gas boiler.

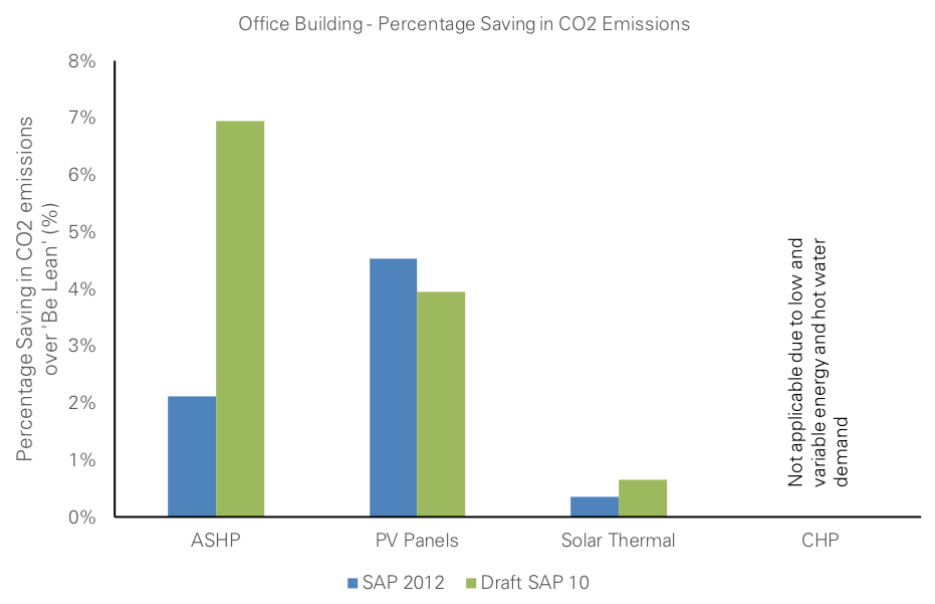

Eight Versa has simulated and compared different energy strategies for both SAP 2012 and draft SAP 10 CO2 emission factors for a residential block and an office building located in central London to illustrate the impacts in practice.

Residential Block

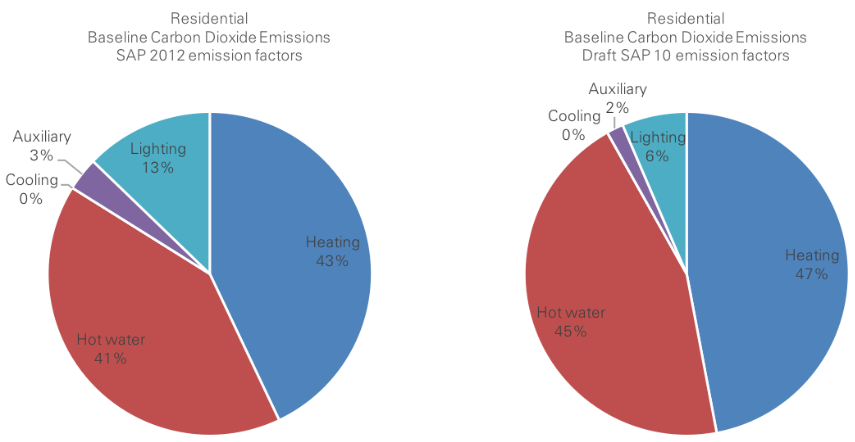

Generally, residential buildings have high space heating and hot water demand. As shown in the pie charts below, space heating is the primary source of carbon dioxide emissions, and hot water is the second. When the development baseline (gas boiler for space heating and hot water) is assessed with the draft SAP 10 carbon figures, electricity and auxiliary (fans and pumps) CO2 emissions are reduced:

Options Appraisal to Reduce CO2

- Due to the high percentage of the heating and hot water, the most efficient energy strategy would be to reduce the carbon emissions by specifying a higher efficiency system such as ASHP or by specifying solar thermal panels. Using the SAP 2012 carbon factors and an ASHP for space heating and hot water, the development can achieve a CO2 saving of approx. 15%. However, when the SAP 10 carbon factors are used, the scheme can achieve a saving of approx. 55% over baseline.

- In this instance PV panels will be less beneficial and will provide a slightly lower improvement compared to the SAP 2012. Solar thermal panels will provide slightly higher percentage savings (using SAP 10) compared to a PV panel system covering the same roof area. Note that this is the exact inverse of solar panel strategies under SAP 2012 where PV were almost always specified alongside a gas boiler because the electricity generated is so valuable in CO2 terms that it substantially offsets the gas consumption. In many schemes the potential CO2 reduction from PV panels and solar thermal is determined by the available roof area. It is very common, in central London projects, to have a tall building with small roof area, resulting in a very poor roof area to internal (energy consuming) floor area ratio. This is frequently the factor limiting urban buildings achieving net zero carbon.

- If the scheme had adequate density to provide consistent hot water demand; 100+ dwellings then a micro or standard-sized CHP could be a CO2 favourable option under the SAP 2012 carbon factors. This is because the CHP could generate electricity using gas (gas had 60% lower carbon factor) and the lower thermal efficiency of a CHP was compensated for by the high value-CO2 electricity generated. The scheme could achieve a CO2 reduction of approx. 40% using a CHP (under SAP 2012 carbon factors). However, under the SAP 10 carbon factors, the electricity produced has lower CO2-value which doesn’t even offset the additional gas burned to generate it.

Generally, heat pumps (for space heating and domestic hot water) would have the highest percentage CO2 reduction, approx. 2.5 times the savings of SAP 2012. The graph below summarises the CO2 reduction results of the applicable technologies for the residential scheme.

Offices in Central London (with Gas Heating)

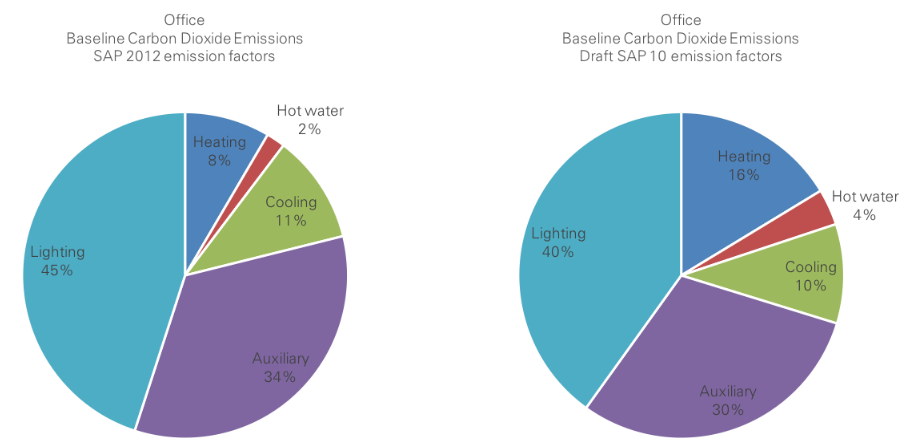

Generally, office buildings have high lighting and auxiliary demand. Heating and cooling are less significant, although this is dependent on the nature of the building fabric, and hot water is almost negligible (except where showers are used). As shown in the graphs below, lighting is the primary source of carbon dioxide emissions, and auxiliary energy is the second largest:

Options Appraisal to Reduce CO2

- An ASHP will have a lower CO2 reduction in the office building compared to the residential building because of the lower space heating demand. However, using the draft SAP 10 carbon figures the scheme can still achieve a relatively significant CO2 reduction. Note that in this scenario gas heating makes limited economic or carbon sense; the cooling system should be designed to provide heating as well, thus simultaneously simplifying the servicing strategy. Electric point of use heaters/boilers now have roughly equivalent CO2 emissions per kWh as gas, thus further removing the carbon incentive to install a gas boiler.

- Similar to the residential case, PV panels will be less beneficial and will provide a slightly lower reduction compared to SAP 2012. Solar thermal panels will not provide a significant reduction because of the low hot water demand.

- The heat demand profile of this scheme (and usually all commercial buildings such as office and retail) is not suitable for a CHP. Therefore, the impact of the CHP has not been assessed.

The ASHP would have the highest percentage CO2 reduction, and if combined with PV panels could provide a reasonable contribution to the CO2 reduction required for planning applications. However, achieving substantial CO2 reductions (i.e. 35%+) will still require optimal passive design and highly efficient lighting and equipment as renewables alone cannot typically achieve the targets. It should also be noted that the new GLA methodology requires schemes to achieve a minimum CO2 saving of 15% through the ‘be lean’ stage. Therefore, efficiency is still driven through the need to reduce the lighting and auxiliary energy demand before applying renewable technologies.

So What Happens Now?

For works that require local authority and planning approval it is unlikely that gas combustion, particularly in the form of CHP, can be shown to be viable in terms of CO2.

With grid electricity nearly at CO2 parity with gas, even simple resistance heating looks favourable on CO2 terms (although explicitly discouraged by GLA policy), a specification that was ludicrous 6 years ago. Moreover, as issues related to air quality, rightly, move higher up the agenda the rationale for installing gas in urban environments decreases further; 38% of central London’s NOx comes from gas combustion (21% for Greater London). Some CHP systems are particularly dire on NOx production and produce many times more NOx than a standard boiler unless a catalytical converter can be installed, which can at best reduce NOx/kWh down to that similar to an average boiler.

Naturally, this change passively affects existing buildings as they will comprise 80%+ of the stock by 2050. The big picture is good news, as all buildings will now be consuming less CO2 in their operation, however, the preponderance of buildings using gas as their primary heating fuel and legacy CHP systems now look a lot worse than their electricity-led counterparts. Nonetheless, this considerable change in the composition of the grid presents a huge opportunity to decarbonise passively and actively.

There is still one aspect where gas wins; consumption cost. With gas rates approximately 4p/kWh vs. 12p/kWh for electricity, gas systems are cheap to install when compared to heat pump systems, and cheap to run when compared to resistance heating. On issues of fuel poverty, gas provides an attractive prospect; committing future tenants, particularly on lower incomes, to electrical energy costs potentially four times more expensive than gas is neither ethical or economically judicious. Consequently, transitioning urban developments from the gas grid to the electrical grid should be preferred, but made conditional on the implementation of energy efficiency standards and measures to reduce demand and operational costs. This approach would sit roughly in the Venn point of grid distribution stress, fuel poverty, air quality and CO2 reduction objectives.

For the foreseeable future there will still be a functional role for gas combustion where electrical capacity on site is limited and the demand for heat and/or temperature is particularly high. However, the evolution of the grid coupled with sector specific policies and regulations such as Building Regulations and the London Plan is not only determining the fuel we choose for schemes, but driving the selection of technologies and adapting the way we design buildings.

Appendix

General calculations showing the benefit of the ASHP using the draft SAP 10 carbon factors:

- A notional gas boiler has an efficiency of 89.5 and an mid-level efficiency ASHP has a CoP of 3. Using the SAP 2012 carbon dioxide emission factors the ASHP would have an improvement on the heating carbon dioxide emissions of approximately 28% over the gas boiler scenario.

- Gas boiler: heating demand / 0.895 * 0.216 = Energy demand * 0.241 kg CO2/year

- ASHP: heating demand / 3 * 0.519 = Energy demand * 0.173 kg CO2/year

- Percentage improvement = (energy demand * 0.173)/(energy demand * 0.241) = 28%

- Using the same efficiencies and the draft SAP 10 figures, the ASHP would have an improvement on the heating carbon dioxide emissions of approximately 67%

- Gas boiler: heating demand / 0.895 * 0.210 = energy demand * 0.234 kg CO2/year

- ASHP: heating demand / 3 * 0.233 = energy demand * 0.077 kg CO2/year

- Percentage improvement = (energy demand * 0.077)/(energy demand * 0.234) = 67%